Remember that I'm no engineer, but I have to say I'm very impressed with the quality of the workmanship on these parts. The fit and finish seems to be absolutely first class with little if any fettling required as far as I can see at this stage. I think I'm going to enjoy this part of the build.

I've

read through the instructions a couple of times to make sure I have a

general idea of what goes where and the first job is to grind in the

slide valves to the cylinder tops (lapping?). This is in order to

get a good steam tight seal around the valve. Surprisingly, there

is no grinding paste included in the kit. I find that a bit odd

since there is a reel of PTFE thread sealing tape in this kit and there

have been other consumables like the loctite glues included in the

other kits. A trip to Halfords reveals that I have to buy a car

valve grinding kit complete with coarse and fine grits and a piece of wood with

two suckers on it. Total cost of £3.99 to just use about 50p

worth of fine paste. Shame really when it could probably have been

included in the kit for next to nothing. Something to think about for

the future perhaps?

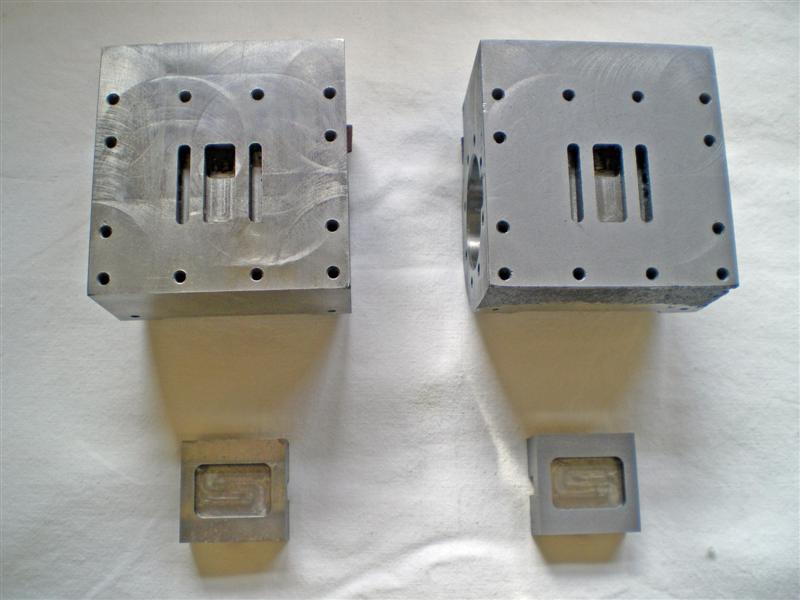

So after about an hour, or so, I've finished lapping the slide valves to the top face of the cylinders. Here's a picture before and after.

Copious amounts of paraffin are used to wash away all traces of the grit using a brush and an old baking dish (well it's old now!)

Next job is to fit the cylinders to the chassis frames. However, there is so much paint in the bolt holes that the bolts won't go anywhere near them. They're a deliberately tight fit so that the cylinders will line up properly. I used a 4.5mm drill in a hand brace to carefully remove the paint without taking any of the metal. The bolts are still a tight fit but with care they will go through the holes. I also used a 3mm drill to clear the holes that will take the draincock operating brackets.

While supporting the weight of the cylinder with one hand, I screwed in one allen bolt to each corner using fingers only at this stage. Then screwed in the remainder hand tight before reaching for the allen key. There's no particular pattern specified but I did the four corners diagonally and then moved alternately from sides to the bottom, tightening bit by bit. I was trying to ensure that all the bolts went in at the same torque - a bit like we used to do when refitting the cylinder head of a car engine. Not sure it was necessary but can't do any harm.

Next is to fit the rear cylinder cover. You'll need a 6BA tube/box spanner for this, it's the only way of reaching the two bolts on the inner edge of the cover, and it's quicker than using an open ended spanner. I spun the bolts in finger tight with the tube spanner and then carefully tightened them using the tommy bar, again working diagonally across the cover to keep things nice and even. I didn't make them too tight, if there's any leaks come steam up time, I can always tighten them a little further, but I don't fancy a broken bolt at this stage!

Now fit the neoprene(?) piston ring to the piston, oil the piston and cylinder, line up from the front of the cylinder and push into place. It goes in quite easily but once in I can't move it with the piston rod. Front cylinder cover is left off at this stage until we get the cross head and connecting rod when I will be able to check all's well. The piston stuffing nut can be screwed in about halfway at this stage.

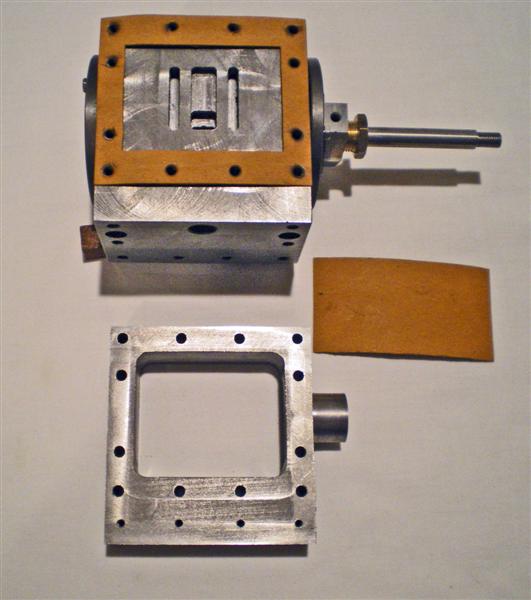

Steam chest and gasket next. The instructions refer to two small gaskets to pack out the gap on the cylinder face between the gasket and the side of the chassis frame. I can't find these but I do find what I thought was a bit of gash gasket material which I'd almost thrown away as it had picked up a couple of deep dents in transit. I cut a 0.5 inch wide strip from this spare piece to fit. The instructions could be a bit clearer for us novices but it all makes sense eventually. The picture shows this more clearly.

The steam chest is temporarily fitted with 4 bolts to hold it in place until we get to do the valve timing and fit the cover permanently.

Now fit the valve rod guide to the motion plate after clearing paint again, this time with an 8mm drill twisted in by hand. The guide goes in from the front of the engine and with the oil hole uppermost (naturally!) The valve nut (the oblong brass nut that goes into the slot in the top of the slide valve) is next and needs a quick clean up with fine emery so that it will fit the slot. The stuffing nut then needs to be screwed partly into the steam chest except that it won't start. The thread is a bit rough where it's been cut and I needed to smooth this out by wrapping a piece of wet and dry round it to smooth it off. We're leaving the graphite yarn packing out at this stage as it will apparently get in the way.

The valve, with the valve nut in place, is then laid on the cylinder face and the valve rod is slid through the valve rod guide, then through the stuffing nut and into the steam chest to screw into the valve nut. Needed to fiddle around a bit here as the valve nut is slightly lower than the valve rod and also keeps moving from side to side. I used a pair of long nosed pliers to carefully grip the ends of the valve nut so that I could line it up with the start of the thread on the valve rod. (Sorry about all the references to valve this, and valve that, but I found it a bit difficult to follow which bit was being talked about in the instructions at times. Perhaps using the full description of each piece makes it a bit clearer)

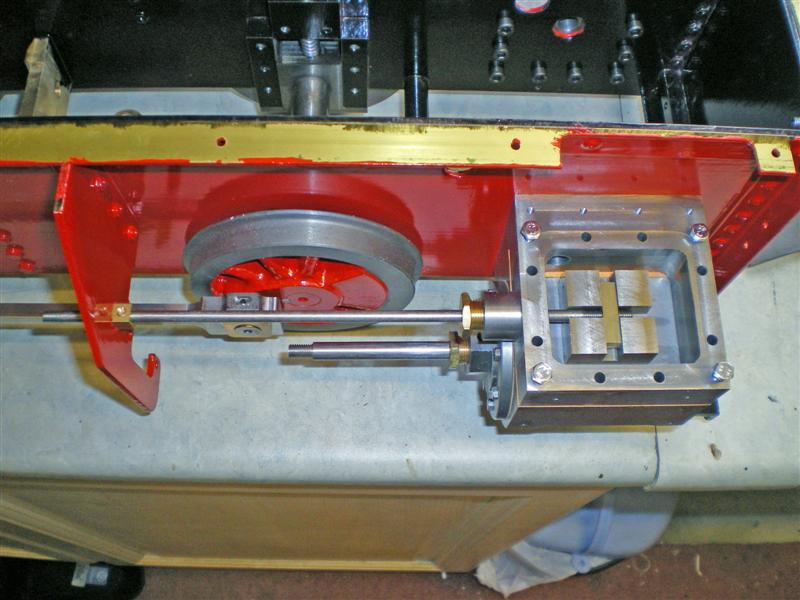

Here's a picture of the finished assembly on the right hand side of the engine. I then repeated the exercise for the left hand assembly.

The instructions now say to fit the draincocks and linkage and it seems to me that the simplest way to do this is to turn the whole engine upside down. However, I'm a bit concerned that this will place some strain on the valve assemblies as the steam chests are only held in place by 4 bolts which will not screw all the way in as the top cover is not yet fitted. If the steam chests drop, I'm worried that all that weight might bend the valve rods so I'm going to wait until I get the next kit until I fit these. Based on past experience with my Polly 2, the draincocks are pretty vulnerable under there anyway and have a nasty habit of biting you if you put your hand anywhere near them. Another good reason for leaving them off for now!

One thing I have realised is that, when comparing what we've done so far with the picture of the prototype on Polly's website (shown on my home page), the piping for the steam inlet and exhaust is completely different. The picture shows it like the Sweet Pea with the pipes coming out of the top of the steam chest, whereas now I've fitted this lot together, I realise that all the pipe work is inside the frames as on my Polly 2. I'm left wondering what the two oblong slots in the footplate are for (see the picture on Kit 2 page), and also what the 4 little screw threaded holes are on the top of the steam chest beside the chassis frame. You can see these in the picture above - answers on a post card please... Andy has said that they would be developing the design from the prototype as they go along so I'm sure all will be revealed in due course.

This beast is beginning to get a bit heavy now - it weighs in at 17Kg, or about 37lbs already. Target weight is around 50Kg if I remember correctly. Will have to find somewhere to park my Polly 2 soon as I'm going to need my hydraulic lifting table before long.

So with the date at March 19th, that's about as far as I can go for now. I'm hoping that kit 5 will be along around the beginning of April and will contain the remaining valve gear so that I might even be able to do a test run on air. So come back soon and see.

Footnote: Geerlig has advised that the steam inlet and exhaust pipes that we can see on top of the steam chests are in fact dummies and will be included in the kits. The 4 small threaded holes are for the flanges of these pipes. He has also advised that I won't be able to test run on air until I've completed kit 6.

Also see new gallery page with pictures of Caroline both prototype and production versions which Geerlig has very kindly sent me to display.